VIBRATORY COMPACTION TABLE

Vibratory Table used for many different type of industries application.

These vibratory tables have been used for the following applications

- powder compaction in boxes

- removing air form concrete moulds

- settle and compact products in bulk bags and bulk boxes

- vibrating ash shakeout system

- Light duty application in Labs and factories

- remove bubbles in sealed containers filled with water

VIBRATORY COMPACTION TABLE

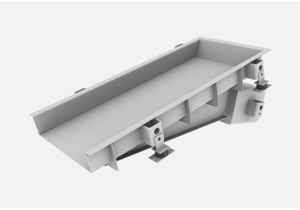

Vibratory Flat Deck Tables

Vibratory Flat Deck Tables from Cleveland Vibrator settle and packs material to lower cost of operations in quality testing, production, packaging and shipping. The most widely used in compaction and densification applications, this model is available in standard and low-profile configurations. The Flat Deck model is typically used to settle materials in cartons, kegs, bulk bags or Gaylord’s but other applications include settling cast table refractory’s in to moulds and eliminating voids and air bubbles from the final moulded product.

Vibratory Flat Deck Tables from Cleveland Vibrator settle and packs material to lower cost of operations in quality testing, production, packaging and shipping. The most widely used in compaction and densification applications, this model is available in standard and low-profile configurations. The Flat Deck model is typically used to settle materials in cartons, kegs, bulk bags or Gaylord’s but other applications include settling cast table refractory’s in to moulds and eliminating voids and air bubbles from the final moulded product.

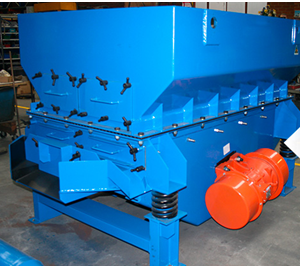

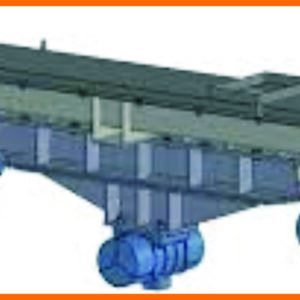

Vibratory Grid Deck Tables

Grid deck vibrating tables are using installed in a roller conveyor system under a hopper-type net weighed or bulk filling station. The empty bulk box, carton or drum is rolled into position over the grid deck which is in the lowered position. Upon starting, the grid deck is raised by inflating air mounts and the load is elevated off the roller conveyor surface. The industrial vibrators are turned on and the contents are compacted or “settled” inside the container. Upon completion of the vibrating cycle, the container is lowered back onto the roller conveyor and advanced to the next operation.

Grid deck vibrating tables are using installed in a roller conveyor system under a hopper-type net weighed or bulk filling station. The empty bulk box, carton or drum is rolled into position over the grid deck which is in the lowered position. Upon starting, the grid deck is raised by inflating air mounts and the load is elevated off the roller conveyor surface. The industrial vibrators are turned on and the contents are compacted or “settled” inside the container. Upon completion of the vibrating cycle, the container is lowered back onto the roller conveyor and advanced to the next operation.

Common Applications Include:

- Settling material in cartons, drums, kegs, and bags before package sealing and shipping

- Removal of air and voids from poured concrete and refractory’s

- Testing product quality and fatigue

Benefits of the Vibratory Table Include:

- Reduction of manual efforts in production or packaging

- Improved production rates and product quality

- Increased quality and consistency in moulded and settled products

- Elimination of broken product and/or broken package rejections

- Removing air from concrete moulds

- Powder compaction in moulds

- Light duty application for labs and factories