MOTORISED BIN ACTIVATOR

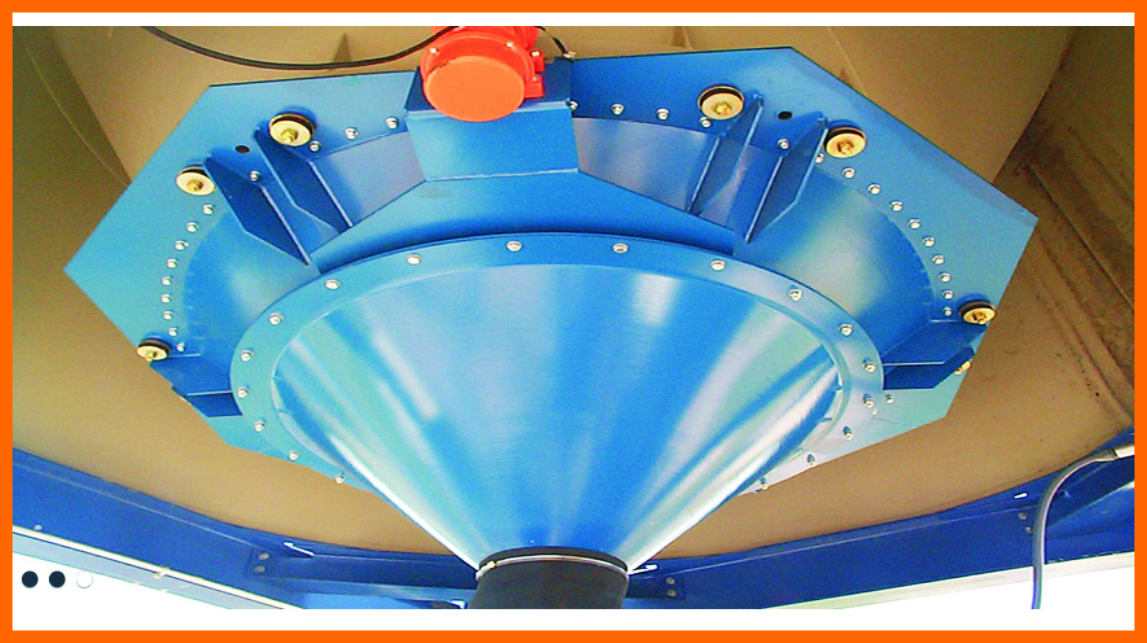

The Bin Activator is a device of tapered conical shape that, due to vibration, facilitates material flow from hoppers or silos. It consists of a seamless carbon or stainless steel cone manufactured on a sheet metal lathe, a seamless SINT engineering polymer seal with integrated upper and lower flange, suspensions for connection with the silo cone, as well as one or two electric motovibrators.

Type: Mining Hopper

Hopper Diameter: 400-2000mm

Diameter of matched silo: 200-2000mm

Application: military and chemical industry, machinery and metallurgy, ceramics, grain and food, plastic industry, wood, building materials, environmental protection and agriculture, etc.

MOTORISED BIN ACTIVATOR

Function

To fit the Bin Activator, the silo cone has to be shorter than usual, leaving a wide outlet section. A flange supplied before or together with the Bin Activator is welded on the silo outlet cone on site. Special suspensions and a seamless, flanged SINT engineering polymer seal form a flexible connection between silo and Bin Activator. One or two electric motovibrators fitted on the unit generate vibration of the Bin Activator every time the feeding device beneath the silo is started for feeding material. During operation the Bin Activator describes a gyratory movement which is transmitted to the material inside the silo. The result is smooth material flow through the Bin Activator outlet into the connected feeder. BA Bin Activators are used in various industrial applications to facilitate discharge of powdery or granular materials from a silo or hopper. The use of this equipment ensures optimum feeding of the material according to a “mass flow” condition, thus avoiding bridging or rat holing phenomena.

DESCRIPTION

BIN ACTIVATOR is a new feeding device for hopper arch breaking, which is installed in the bottom of stock bin. It is used for arch breaking and uniform feeding, and to solve the problem of material storage difficulties. Suitable for any types of storage bin, such as round, square, steel or concrete.

Advantages

1. The material can discharge continuously and smoothly, no flow material occlusion and particle size

segregation.

2. The bin height can be reduced greatly, is advantageous to the factory craft arrangement.

3. With simple structure, reliable operation, stable operation.

4. Less power consumption, long service life, maintenance is simple.

5. The discharge amount is stable in + 5%;

6. Equipped with electrical control equipment, no parking impact.

7. Environmentally friendly: can achieve completely sealed transport, no dust overflow.

Benefits

- High discharging performance

- No waste material thanks to special seal design

- Reduced maintenance thanks to long-life seal material

Technical features/Performance

- Diameters up to 1850mm

- 304L SS available for additives

- Strong seamless seal

- No internal residue nests

- Smooth internal finishing