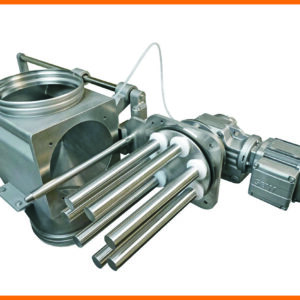

PERMANENT MAGNETIC MAGNAROLL

In our extensive product range, we are involved in providing a wide range of Magnetic Roll Separator. Specially design to recover ferromagnetic materials, the offered roll separator is designed and manufactured by our professionals as per the set market norms by utilizing best quality raw material and latest technology. This roll separator is provider in different stipulations; this can also be customized as per the needs of the customers.

Product Detail

Brand: Matech Equipments.

Capacity: 50 microns up to 100mm.

Diameter: 75mm. , 100 , and 150mm.

Length: Up to 1500mm.

PERMANENT MAGNETIC MAGNAROLL

Operation process

The raw material flow into feeding entrance, then it land on the belt, through the belt conveyor to the magnetic roller. Then all iron material in the raw material adsorbed on the magnetic pole, last it follow the belt running to the non-magnetic area, and the iron material will automatically fall into the iron box.

Other Details:

- Compact construction

- Single or multi stage separation

- Fully enclosure with dust extraction port

- Designed for easy maintenance

- Automatic belt tensioning and tracking

- Tool free belt change

Application scope

Applicable for dry powder iron removal in ceramic industry quartz sand refractory of non-metallic materials the iron removal of Scrap metal.

Magnetic Drum Separator are primarily designed and manufactured as low field intensity separators. They have an open magnetic system with the magnetic poles located in one plain. Low field intensity separators are employed for separating iron particles from bulk material whenever foreign iron disturbs the subsequent process sequences.

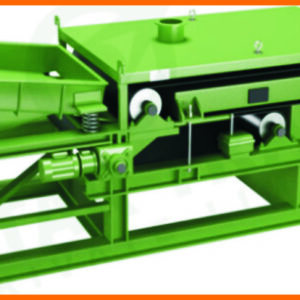

We are manufacturers and Suppliers of Double Roller Magnetic Separator and roller magnetic separator in India offering a wide range of superior products. Our machines are carefully designed and fabricated which are highly appreciated not only in the Indian market but also on a global scale.

Product characteristic

1. The machine is durable .

2. Fit for raw material of big grain.

3. Structure simple and easy to operate.

4. The magnetic field area is large and the magnetic force is strong .

Operation process

The raw material flow into feeding entrance, then it land on the belt, through the belt conveyor to the magnetic roller.

Then all iron material in the raw material adsorbed on the magnetic pole, last it follow the belt running to the non-magnetic area, and the iron material will automatically fall into the iron box.

Application scope

Applicable for dry powder iron removal in ceramic industry quartz sand

refractory of non-metallic materials the iron removal of Scrap metal.