-

SAND WASHING PLANT

BUCKET ELEVATOR

MATECH Bucket Elevators feature heavy duty components, jig welded for easy assembly. All pieces are Mild steel for a durable finish and long, maintenance free life. The Matech design provides the ideal Material discharge for the based on the rated capacities.

-

VIBRATORY EQUIPMENTS

CIRCULAR VIBRATORY SCREEN

Circular Vibrating Screen : combines the characteristics of the vibrating and rotary screens. Both are compact independent machines carrying out high precision mechanical separation processes, according to particle size, and applying the effective technique of multi plane inertial vibration.

Working principle : It was based on the vertical vibration motor as vibration source. There are two eccentric hammers on the Vertical vibration motor. Can produce horizontal, vertical, slope of three dimensional movement. Because of its special

vibration form, material movement and amplitude can be adjusted to meet different process of requirements. -

MAGNETIC EQUIPMENT

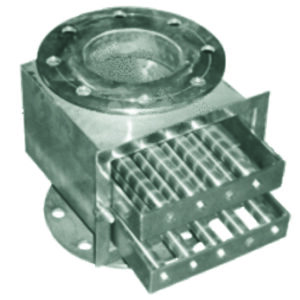

DRAWER MAGNET

(Super Intensity Rare Earth for pipeline) (For chutes / pipeline with free flowing material application)

The Drawer magnetic bar of the machine adopt stronger rare earth permanent magnet or oxidational magnetic iron as the source of magnet. Compared with the electromagnetic iron machine, it can save power consumption. Using super magnetic force, it sort out the tiny iron impurity, so as to protect the next mineral processing separator equipment and enhance the purity of material. -

MAGNETIC EQUIPMENT

Drum Type Magnetic Separator

Magnetic Drum Separators are of self-cleaning type and provide continuous removal of ferrous contamination from a wide range of free-flowing bulk and granular materials in high-volume applications. Drums can be ordered with or without housing. agnetic Drum Separator system is a complete machine with Stainless Steel 304 / 316 Housing & Drive system. Only drum separator unit can also be supplied. The Drum Separators are available in two types:

High Intensity – (Ndfeb Magnet– 4500 gauss), for Operating Temperature of 80°C(Max.)

Low Intensity – (Ferrite Magnet -1200 gauss), for Operating Temperature of 250°C(Max.)

Ferrous fine particles, nuts, bolts, pins, nails and other tramp metal from free-flowing granular material can be arrested effectively. -

VIBRATORY EQUIPMENTS

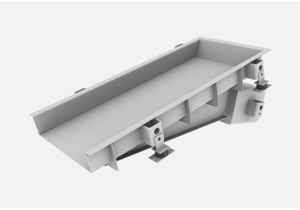

Electro Drive Vibrating Feeder Unit

Matech vibrating feeders with electromagnetic drive are used for bin extraction and for conveying of bulk material. Especially favourable for dosing, applications include feeding of weigh bins, or weigh feeders, or steady and smooth feeding for downstream equipment. The vibrating feeders are manufactured in a welded design, driven by an Matech electromagnetic drive.

Advantages

- infinite variable feed rate with constant volume

- automatic cut off of bin discharge at standstill

- low electric power consumption

- no electric losses

- high feed rate

- maintenance free – no rotating parts

- minimized wear

-

VIBRATORY EQUIPMENTS

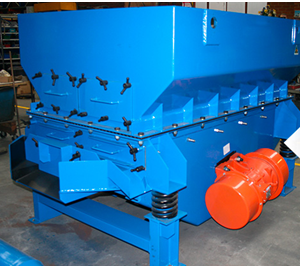

GRIZZLY FEEDER & VOLUMETRIC FEEDER-DOSING FEEDER

The nar-rcco-m Vibrating Feeder is a kind of linear direction feeding equipment. It can send shaped and granule materials into crusher evenly, timely and continuously as well as screen the materials roughly. The vibrating feeder is widely used in crushing and sieving production line such as metallurgy, building material, chemical industry, coal, mining and grinding industry.

Type: Grizzly Feeder

Capacity : 50-480 t/h

Feeding Granularity : 400-800mm

Application: widely used in hydropower industry, building Materials,metallurgy, mining, gravel field, chemical industry, crushing, screening production line, etc -

MAGNETIC EQUIPMENT

HOPPER MAGNET

Designed for different industries, the hopper magnet protects molding machinery and other processing equipment from damaging ferrous metal separation and can be conveniently monitored through the transparent drawer face. Slide gate shuts off product flow and is provided as a standard feature. An easy clean design is available.

-

MAGNETIC EQUIPMENT

Hump Magnets

Hump Magnets generally consist of two Plate Magnets mounted in an offset housing and are installed in vertical spouts. As product enters the housing it impacts directly on the face of the first Plate Magnet, travels through the offset angle of the housing and impacts directly on the face of the second Plate Magnet. This provides excellent separation results for high volume, poor flowing, or abrasive materials.

-

VIBRATORY EQUIPMENTS

KNOCKOUT TABLE

We are one of the leading manufacturers and suppliers of Vibrating Knockout

Machine. Our supplied Vibrating Knockout Machine is powered by electric motor for

smooth functioning. The offered Vibrating Knockout Machine is capable of

hammering to clean the castings. Our offered machine is available at competitive

market prices.Product Type:

Model No Deck Size mm Deck Loading Capacity kg Vibratory Motor ME-KO-01-01 1000 x 1000 1 Ton 2 HP (2 Nos) ME-KO-02-02 2000 x 2000 3 Ton 3 HP (2 Nos) ME-KO-02-25 2000 x 2500 8 Ton 5 HP (2 Nos) ME-KO-03-03 3000 x 3000 18 Ton 7.5 HP (2 Nos) ME-KO-03-04 3000 x 4000 25 Ton 10 HP (2 Nos)