VIBRATORY CONVEYORS & TWO WAY VIBRATING CONVEYOR

Two-way vibratory feeders or conveyors have substantial applications in a variety of fields. One typical

application is in foundry operations. For example, castings may be delivered to the feeder or conveyor at a

location intermediate its ends and then the feeder or conveyor energized to feed the castings to one end or the

other depending upon where it is desired to locate the casting.

Chemicals – Conveying of scrap plastic pellets of fiberglass in reprocessing system, conveying and scalping

foreign matter from chemicals at bag dump stations.

Food – Conveying of multiple ingredients for blending while conveying. Transfer of bulk ingredients from weight

hopper to mixer, conveying freeze-dried of spray dried food product of storage area.

Foundry – Conveying sand in primary and sand processing system, conveying small casting from shake out

areas, conveying scrap to charging area.

Automotive – Parts conveying in blanking and punching operations. Conveying parts to plating operation, flux

conveying in automatic welding machines.

Concrete – Conveying dry ingredients (cement, sand, gravel) to weigh batch hoppers. Distribution of steel

reinforcing particles in concrete batching and mixing operations.

Steel- Mill scale conveying units under strip and bar operations.

VIBRATORY CONVEYORS & TWO WAY VIBRATING CONVEYOR

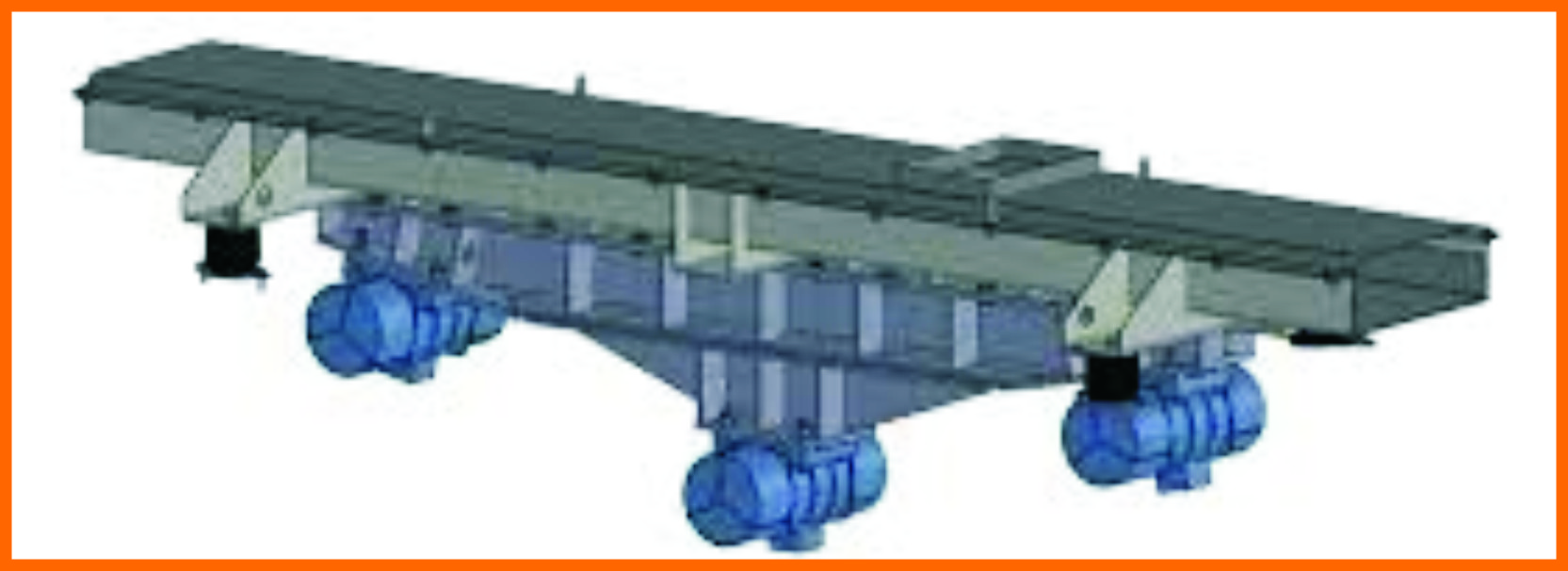

TWO WAY VIBRATORY CONVEYOR

Anew innovative vibrating equipment design from matech conveys in either direction with

a quiet, smooth, horizontal motion without dusting or damage to friable materials. Direction of material flow is

easily and immediately reversible at the touch of a button controlling the rotational direction of a single, low

horsepower, self-contained drive. Smooth horizontal material flow makes a TWO-WAY unit ideal for moving

a variety of bulk materials including powders, chemical or food products. Minimal vertical acceleration force

also permits the noise-free movement of castings, sprue and other metallic parts with reduced trough wear.

Conveying motion is essentially horizontal, with minimum vertical acceleration, resulting in gentle, noise free

“shuffling material movement without bouncing. Vertical forces, less than gravity make the unit ideal for

handling fine materials, which would tend to aerate and be difficult to handle in a conventional vibrating

conveyor.

These appliances are used to transport loose products in two different Directions.

They are particularly useful for transporting loose products.

They are suitable whenever the flow rate does not need to change during operation.

Options: appliances set on the floor or hung, pipe with axial outlet or several intake manifolds.

Advantages: No mechanical parts, perfect seal, no retention, flow with regular quantity and possibility of changing during operation by control via frequency regulator according to various parameters. Low power consumption, very long service life, low maintenance.

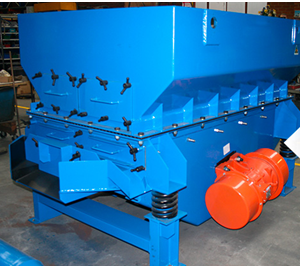

FEATURES

- Uses a single low horsepower drive, reducing energy consumption.

- Available in curves up to 90 degrees.

- Horizontal stroke does not damage fragile product