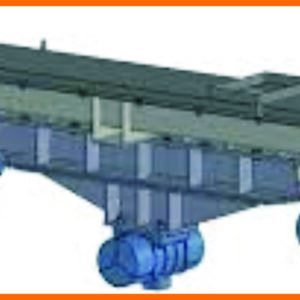

GRIZZLY FEEDER & VOLUMETRIC FEEDER-DOSING FEEDER

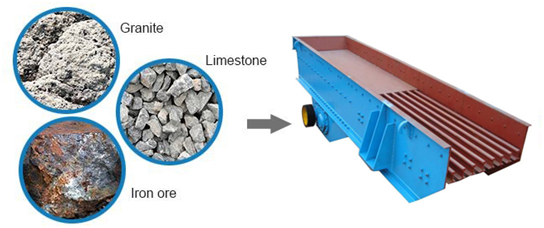

The nar-rcco-m Vibrating Feeder is a kind of linear direction feeding equipment. It can send shaped and granule materials into crusher evenly, timely and continuously as well as screen the materials roughly. The vibrating feeder is widely used in crushing and sieving production line such as metallurgy, building material, chemical industry, coal, mining and grinding industry.

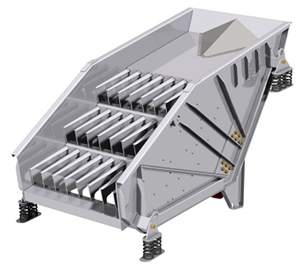

Type: Grizzly Feeder

Capacity : 50-480 t/h

Feeding Granularity : 400-800mm

Application: widely used in hydropower industry, building Materials,metallurgy, mining, gravel field, chemical industry, crushing, screening production line, etc

GRIZZLY FEEDER & VOLUMETRIC FEEDER-DOSING FEEDER

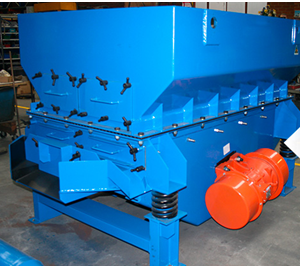

Features

1.Smoothly vibrating and long service life

2.Vibrating force adjustable, easy to operation.

3. Low noise and power consumption

4. Simple structure, easy to maintenance.

Working Principle

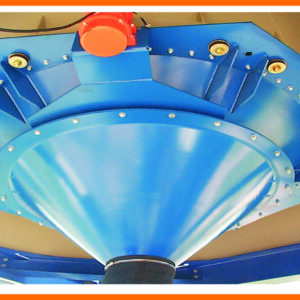

Vibrating feeder is made of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator consists two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. By drive of the motor, the two eccentric shafts start rotating to generate a linear huge power which forces the feeder to vibrate back and forth. Through the vibration, The materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller material will fall down, avoiding the further crushing, so screening purpose is reached.

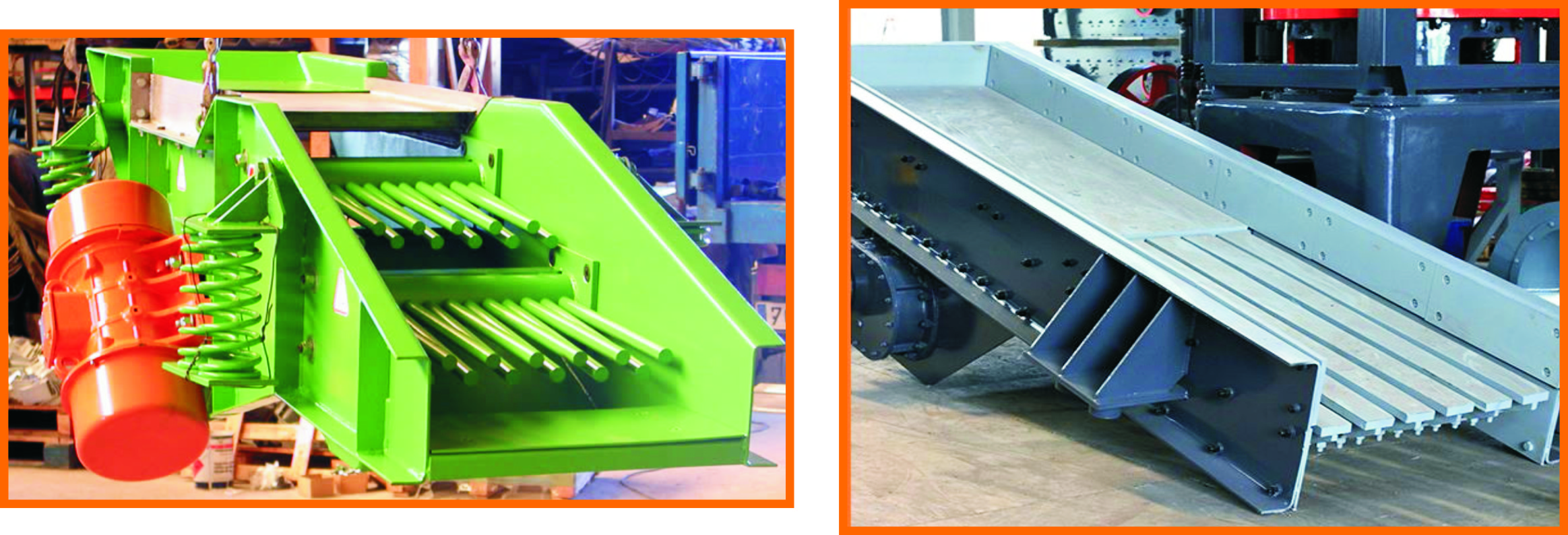

Matech vibrating grizzly – pre-screens with unbalance motors are used for extraction under hopper and for separating the product in a processing line. This vibration is used as the power to make the material slide on the material chute and drop so that the material moves forward continuously. As a result, material feeding purpose is realized. When the material passes the screen bars of the chute body, smaller pieces of material will drop from the gaps between the screen bars and not enter the next breaking procedure. In this way, material screening result is achieved.

Settings: the amplitude is mechanically adjusted by angular displacement of the unbalance of the electromechanical vibrator.The transport trough of the conveyor is divided into two parts: a receiving area for extraction followed by one or more grids of bars for separating blocks and fines.

Options: equipments installed or hung, open or closed, with or without wear-resistant coating or others (synthetic rubber etc.).

Performance : Inclined from 0° to 10° can improve the performance of the equipments in certain cases.

Advantages: Constant volumetric flow. To avoid jamming in the grid, the bars are positioned divergently in the direction of flow of the product.