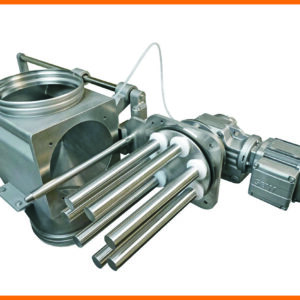

Hump Magnets

Hump Magnets generally consist of two Plate Magnets mounted in an offset housing and are installed in vertical spouts. As product enters the housing it impacts directly on the face of the first Plate Magnet, travels through the offset angle of the housing and impacts directly on the face of the second Plate Magnet. This provides excellent separation results for high volume, poor flowing, or abrasive materials.

Hump Magnets

The drawback to the Hump Magnets is they typically require a long straight area for installation. The two Plate Magnets are hinged, latched, and gasket to the housing for access.

Hump Magnets (Plate-In-Chute Separators) Plate magnets can be provided with engineered chutes to fit directly into your processing lines. Customer specified inlet and outlet requirements can be accommodated using custom designed housings, transitions (round or rectangular), flanges and more. Housings and chutes are available for single plate magnets, multiple plate magnets and for Manual,

Self-Cleaning models Clean and Self Cleaning Spout Magnets are designed to simplify the cleaning process and to increase processing line efficiency. These cleaning options feature spout faced stripper pans that swing out of the product flow and away from the magnet to release collected metal. The Self-Cleaning model operates on the same principle but uses either pneumatic cylinders or electric actuators to open and close the plate magnet at user specified intervals

FEATURES

- All stainless steel construction

- Ceramic or Rare Earth Magnets

OPTIONS

- Mild steel construction

- Food Grade Finish

- Pre-drilled Flanges

- Round inlet and outlet transitions

- Rectangular or square transitions

- Self-Cleaning design