RECTANGULAR LIFTING ELECTRO MAGNET

Billets and Rails

For handling single layers of steel billets and rails in raft format, Rectangular Lifting Magnets are the ideal solution.The advantage of Rectangular Magnets is that the-face width of the magnet can be utilized for lifting the billets and rails. This

features aids handling and improves operational availability. Rectangular Lifting Magnets are also suitable for handling rafts of billets at temperatures upto 600°C. When uniform stacking of billets is unimportant, Circular Lifting Magnets can ! – used.

RECTANGULAR LIFTING ELECTRO MAGNET

Slabs, Blooms and Ingots

Hot ingots and slabs are handled by Rectangular Lifting Magnets. Ingot casting moulds are also handled with Rectangular Lifting Magnets both before and after the casting process. Steel blooms are most effectively handled by means of Rectangular Magnets

Hot ingots and slabs are handled by Rectangular Lifting Magnets. Ingot casting moulds are also handled with Rectangular Lifting Magnets both before and after the casting process. Steel blooms are most effectively handled by means of Rectangular Magnets

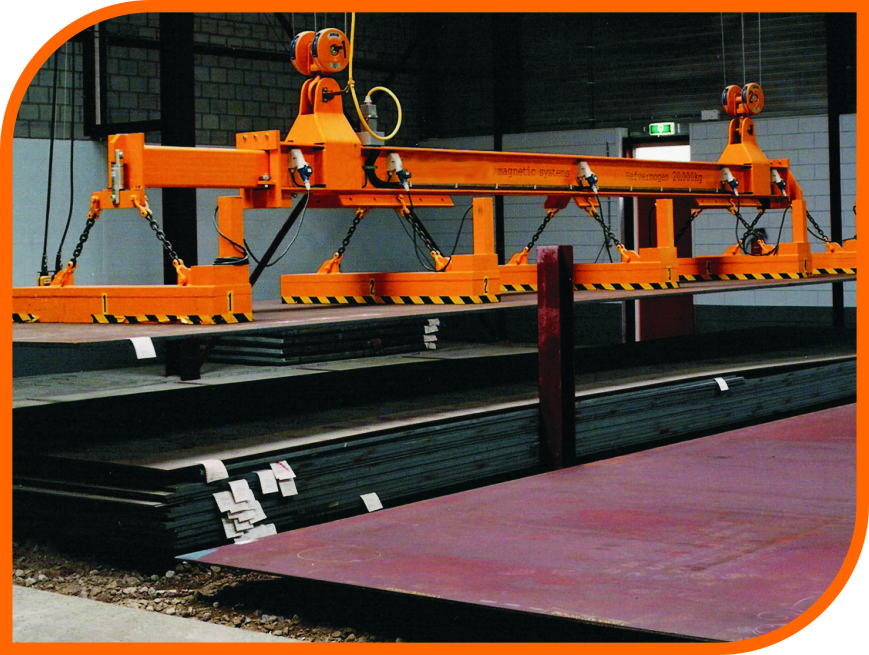

Plate Handling

Large Plates are handled either by Circular or Rectangular Lifting Magnets. Normally more than one magnet is used, particularly when complex manipulation such as turning for inspection of each side is required. With special control Gear designed by us, a pack of unstrapped plates can be lifted and released individually in a controlled manner. To handle thin plates (from 3mm-12 mm thick) when minimal

Large Plates are handled either by Circular or Rectangular Lifting Magnets. Normally more than one magnet is used, particularly when complex manipulation such as turning for inspection of each side is required. With special control Gear designed by us, a pack of unstrapped plates can be lifted and released individually in a controlled manner. To handle thin plates (from 3mm-12 mm thick) when minimal

bending or deflection is important. In profiling shops, the full plate may be lifted with all magnets onto the profiling bed and selected magnets switched to lift individual pieces, parts or scrap. Rectangular magnets are used to handle plate from 5-150mm thick in si/es upto 4m by 30m long.