Spiral Elevators

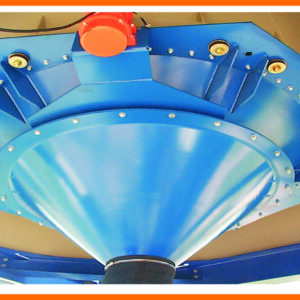

Spiral elevator for vertical transport of fine bulk material The spiral conveying trough is driven by unbalanced motors arranged oppositely causing a vertical conveying of the bulk material. Inlet and outlet are designed according to customers needs. spiral elevators are used in foundries and in the commodity industries.

Advantages

robust design may be manufactured in a variety of materials low power consumption low maintenance low space requirement

Spiral Elevators

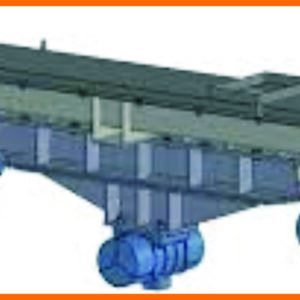

Vibrating Spiral Elevators are designed for conveying bulk material within a compact area. The machine eliminates egradation during. elevation by utilizing a gentle vibratory motion. The helical Pattern of the Spiral Elevator’s trough creates a long conveying path with a high retention time that makes it ideal for cooling, heating, or drying

processes. Several. heat treatment options are available. These include air vents for direct heating/cooling and jacketed flights for contact heating/cooling via water, or steam.

Therefore designs may vary depending on the process, material, conveying path, and the various surrounding conditions.

Benefits

- Gentle vibratory motion maintains material integrity

- Small workspace footprint

- Low maintenance – high quality, efficient, reliable drives

- Long conveying path is ideal for thermal treatment

- Conveying velocity is electronically adjustable using a variable frequency drive

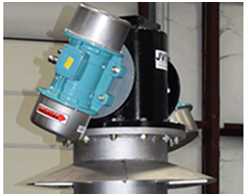

The motorized spiral conveyor we offer a number of spiral trays which is manufactured using mild steel. The main body attached with vibrating motor is linked to the upper spiral tray body. As the Motor starts, the vibration sets the material in spiral upward motion. The body housing of the motor is enclosed to prevent from dusting. The motorized spiral conveyor screen works on standard frequency of 3000 vibration per minute with max. amplitude of 1.5 mm. to 2 mm. depending on the size of the screen.

- Application Areas

- Plastics

- Rubber

- Ceramic

- Food

- Pharmaceutical

- Chemical

- Fertilizer

- Glass industries