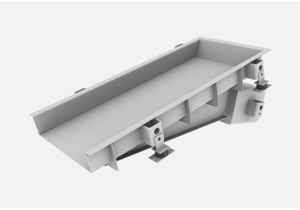

VIBRATORY FURNACE CHARGER/VIBRATING TABLE

Our assortment of vibrating equipments also includes Furnace Charger, which provides an effective solution to high labor cost and risk faced by furnace operators during foundries, melting shops and others. Available in customized options, our vibratory furnace charger is manufactured using high grade raw material.

VIBRATORY FURNACE CHARGER/VIBRATING TABLE

We offer Vibratory furnace charger (VFC) in various capacities. A Self bottom opening bucket is provided to charge the vibratory charger. This bucket will carry the charge material of required ratio, directly from the stock yard and place it on the charger structure. The bottom opening door arrangement will automatically open when it placed on the feeder structure and the Raw material falls in the vibratory trough. The raw material will then moves to the furnace when it operates. The advantage of this vibratory furnace charger is that the charge floor is neat and clean. No man power required to charge the furnace. The vibratory charging system is equipped with a variable drive PLC and control panel that helps to charge the raw material to the furnace gradually or bulk. Our VCF (vibratory furnace charger) has been appreciated for its functionality and its ability to reduce charging time and hence enable to enhance:

1) VIBRATORY FURNACE CHARGER

Vibratory Furnace Chargers are a cost effective method of increasing productivity and quality of melt. The Furnace Charger consists of Storage Hopper with Vibrating feeder mounted on a mobile Trolley which moves to and fro between scrap yard and the furnace

The metallic components like scrap, bales, pig iron and foundry retains are stored in the hopper. The hopper shape is specially designed to enable bulky and irregular scrap pieces to be extracted without problem. Vibratory furnace charger is effective solutions to problems such as high labour cost, hazards operators faced in foundries, melting shops etc.

The Furnace Charger consist of charging car and comprises of a discharge chute with Vibrating Feeder for the metallic components and the Hopper all mounted on a travelling motorized trolley.

The discharge snout is inclined and forms a rounded trough to discharge material uniformly over the width. The feeders are driven by Unbalance Motors.

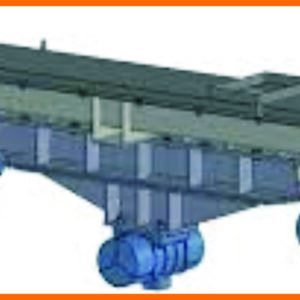

2) VIBRATORY CHARGER FOR OPEN DOGHOUSE

DESCRIPTION

The MATECH vibratory batch charger is a solid and reliable charger for cold batch into side or end-fired furnaces. The charger can therefore be used at regenerative, recuperative or oxy-fuel furnaces with a lateral or frontal open doghouse.

The operating principle is to feed the batch into the doghouse via a vibratory chute and push it onto the glass surface into the furnace via a water-cooled paddle. The end piece of the vibrating chute is made of heat resistant steel and is exchangeable.

FEATURES

- Reduction of the amount of dust by batch piles

- Reduction of heat loss due to thermal heat shield

- Durability due to stable construction, utilization of high quality components and excellent workmanship

- Increased melting rate by means of melting of smaller portions of mixture and uniform distribution via swing gear