-

MAGNETIC EQUIPMENT

PERMANENT MAGNETIC CONCENTRATOR

We are counted amid the reputed Permanent Magnetic Separators and Concentrator Magnetic Separator Manufacturing & Suppliers. Permanent Magnetic Concentrator Separator is widely used for upgrading or concentrating material containing a very high percentage of magnetic or where magnetic/mechanical agitation is required for the separation of many difficult materials. Concentrator Magnetic Separator or Permanent Magnetic Separator is ideal for the upgrading of sponge iron/cast iron borings, steel/brass/aluminium turnings, chips and for mineral beneficiation applications such as the purification of dry ceramic and refractory materials, reclamation of abrasive grains, removal of iron contamination from chemical powders and PERMANENT MAGNETIC CONCENTRATOR grains and for many other such applications requiring maximum separation with a minimum product loss. The Concentrator Magnetic Separators can be purchased in various technical specifications from us

-

MAGNETIC EQUIPMENT

PERMANENT MAGNETIC MAGNAROLL

In our extensive product range, we are involved in providing a wide range of Magnetic Roll Separator. Specially design to recover ferromagnetic materials, the offered roll separator is designed and manufactured by our professionals as per the set market norms by utilizing best quality raw material and latest technology. This roll separator is provider in different stipulations; this can also be customized as per the needs of the customers.

Product Detail

Brand: Matech Equipments.

Capacity: 50 microns up to 100mm.

Diameter: 75mm. , 100 , and 150mm.

Length: Up to 1500mm. -

MAGNETIC EQUIPMENT

PLATE MAGNET

Protect against contamination in processing lines. Matech Plate Magnets can be used in sloped or vertical chutes, ducts, feed tables,over conveyors, or in other strategic locations to remove ferrous contaminants and damaging tramp metal.

-

MAGNETIC EQUIPMENT

PRONG MAGNET FOR LIQUID SLURRY

We are manufacturer and supplier of Prong Magnets to our huge clientele base. It is precisely engineered using latest technology and machinery at our unit under the guidance and supervision of our experts. It is useful to connect directly to the pipe line of various sizes. Prong Magnets find application for Starch Products, Fruit Processing Juice, Kerosene, Chemical Slurry/Liquid and a lot more. Furthermore, we strive to supply these magnets to within given time frame in secure packaging.

-

MAGNETIC EQUIPMENT

RECTANGULAR LIFTING ELECTRO MAGNET

Billets and Rails

For handling single layers of steel billets and rails in raft format, Rectangular Lifting Magnets are the ideal solution.The advantage of Rectangular Magnets is that the-face width of the magnet can be utilized for lifting the billets and rails. This

features aids handling and improves operational availability. Rectangular Lifting Magnets are also suitable for handling rafts of billets at temperatures upto 600°C. When uniform stacking of billets is unimportant, Circular Lifting Magnets can ! – used. -

MAGNETIC EQUIPMENT

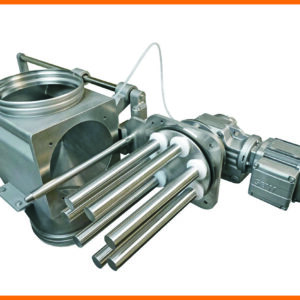

ROTARY CLEAN FLOW MAGNETS

Designed to remove iron contaminated impurities from powders and granulates. The magnets, axially magnetised permanent magnet rings, are assembled into magnetic rods.

The magnets are insulated from the outside by a thin wall stainless steel cylinder. The rods are mounted on base plates in a staggered manner and the rotation of such a cage arrangement improves the flow through a pipe.

Cleaning is easily performed by retraction of the magnetic rods from the stainless steel casing. Used predominantly in the foodstuffs industry. You can see on the video the operation principle and easy cleaning of Cleanflow magnet with rotation magnetic bars, for avoiding metal pollution in your product. It is available also in a hygienic and hydro formed housing. It is especially used in the baby food and the dairy industry. -

-

VIBRATORY EQUIPMENTS

Spiral Elevators

Spiral elevator for vertical transport of fine bulk material The spiral conveying trough is driven by unbalanced motors arranged oppositely causing a vertical conveying of the bulk material. Inlet and outlet are designed according to customers needs. spiral elevators are used in foundries and in the commodity industries.

Advantages

robust design may be manufactured in a variety of materials low power consumption low maintenance low space requirement -

MAGNETIC EQUIPMENT

SUSPENSION MAGNET

slisnension Mannet Suspension Magnets and over band Magnetic Separator are back bone of continuous process industry. The permanent Magnetic Suspension magnets are suspended over conveyor line and are used to remove iron impurities mixed with product moving with conveyor belt. it can be also used for any other material feeding system to avoid damage to the crushers, grinders and other material handling equipment. These magnets can be made in self-cleaning design if required(over band Magnetic Separator).

-

MAGNETIC EQUIPMENT

TUBE MAGNETS FOR PIPELINE SYSTEM

(with Super Intensity Rare Earth magnets)

We are able offer our clients a wide range of Tube Magnets For Pipelines. These are specially developed for thorough removal of ferrous metals from material in granular and powder form during transportation through pipeline systems. The offered magnet systems conform their adherence with international quality standards. Moreover, the guide strips in the pipelines are fitted on the inside of housing to ensure that material to be purified is well distributed and comes into good contact with magnet core. The standard type of our products have M.S. steel housing as an alternative version with a stainless steel (S.S.-304/S.S.-316,S.S.-316-L) housing. -

VIBRATORY EQUIPMENTS

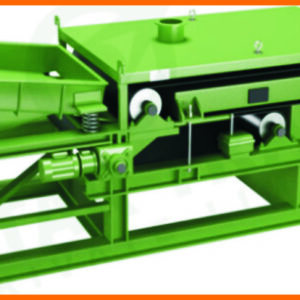

VIBRATING TABLE

( Electro Magnetic Type / Unbalance Motorised Version )

Grid top tables:- Automatic operation. -Adaptable to any roller conveyor. -Light weight yet strong. The “matech equipments” Grid Top Table is designed to fit between the rollers of your conveyor. The load foundry flask, drum or box is rolled into position. Air mounts lift the grid top and take the load off the rollers. The vibrators are activated and the load vibrated. Air mounts are deflated and the load is back on the conveyor ready to be moved along. All done in seconds without handling. The matech equipments’ design uses strong light weight rectangular tubing for more vibration transfer to the load.