-

VIBRATORY EQUIPMENTS

Spiral Elevators

Spiral elevator for vertical transport of fine bulk material The spiral conveying trough is driven by unbalanced motors arranged oppositely causing a vertical conveying of the bulk material. Inlet and outlet are designed according to customers needs. spiral elevators are used in foundries and in the commodity industries.

Advantages

robust design may be manufactured in a variety of materials low power consumption low maintenance low space requirement -

MAGNETIC EQUIPMENT

SUSPENSION MAGNET

slisnension Mannet Suspension Magnets and over band Magnetic Separator are back bone of continuous process industry. The permanent Magnetic Suspension magnets are suspended over conveyor line and are used to remove iron impurities mixed with product moving with conveyor belt. it can be also used for any other material feeding system to avoid damage to the crushers, grinders and other material handling equipment. These magnets can be made in self-cleaning design if required(over band Magnetic Separator).

-

MAGNETIC EQUIPMENT

TUBE MAGNETS FOR PIPELINE SYSTEM

(with Super Intensity Rare Earth magnets)

We are able offer our clients a wide range of Tube Magnets For Pipelines. These are specially developed for thorough removal of ferrous metals from material in granular and powder form during transportation through pipeline systems. The offered magnet systems conform their adherence with international quality standards. Moreover, the guide strips in the pipelines are fitted on the inside of housing to ensure that material to be purified is well distributed and comes into good contact with magnet core. The standard type of our products have M.S. steel housing as an alternative version with a stainless steel (S.S.-304/S.S.-316,S.S.-316-L) housing. -

VIBRATORY EQUIPMENTS

VIBRATING TABLE

( Electro Magnetic Type / Unbalance Motorised Version )

Grid top tables:- Automatic operation. -Adaptable to any roller conveyor. -Light weight yet strong. The “matech equipments” Grid Top Table is designed to fit between the rollers of your conveyor. The load foundry flask, drum or box is rolled into position. Air mounts lift the grid top and take the load off the rollers. The vibrators are activated and the load vibrated. Air mounts are deflated and the load is back on the conveyor ready to be moved along. All done in seconds without handling. The matech equipments’ design uses strong light weight rectangular tubing for more vibration transfer to the load. -

VIBRATORY EQUIPMENTS

VIBRATORY COMPACTION TABLE

Vibratory Table used for many different type of industries application.

These vibratory tables have been used for the following applications- powder compaction in boxes

- removing air form concrete moulds

- settle and compact products in bulk bags and bulk boxes

- vibrating ash shakeout system

- Light duty application in Labs and factories

- remove bubbles in sealed containers filled with water

-

VIBRATORY EQUIPMENTS

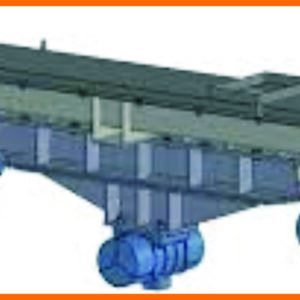

VIBRATORY CONVEYORS & TWO WAY VIBRATING CONVEYOR

Two-way vibratory feeders or conveyors have substantial applications in a variety of fields. One typical

application is in foundry operations. For example, castings may be delivered to the feeder or conveyor at a

location intermediate its ends and then the feeder or conveyor energized to feed the castings to one end or the

other depending upon where it is desired to locate the casting.

Chemicals – Conveying of scrap plastic pellets of fiberglass in reprocessing system, conveying and scalping

foreign matter from chemicals at bag dump stations.

Food – Conveying of multiple ingredients for blending while conveying. Transfer of bulk ingredients from weight

hopper to mixer, conveying freeze-dried of spray dried food product of storage area.

Foundry – Conveying sand in primary and sand processing system, conveying small casting from shake out

areas, conveying scrap to charging area.

Automotive – Parts conveying in blanking and punching operations. Conveying parts to plating operation, flux

conveying in automatic welding machines.

Concrete – Conveying dry ingredients (cement, sand, gravel) to weigh batch hoppers. Distribution of steel

reinforcing particles in concrete batching and mixing operations.

Steel- Mill scale conveying units under strip and bar operations. -

VIBRATORY EQUIPMENTS

VIBRATORY FEEDER

A vibratory feeder is an instrument that uses vibration to “feed” material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, either down, or down and to a side, and then vibration is used to move the material. They are mainly used to transport a large number of smaller objects. A belt weigher are used only to measure the material flow rate but weigh feeder can measure the flow material and also control or regulate the flow rate by varying the belt conveyor speed.

-

VIBRATORY EQUIPMENTS

VIBRATORY FURNACE CHARGER/VIBRATING TABLE

Our assortment of vibrating equipments also includes Furnace Charger, which provides an effective solution to high labor cost and risk faced by furnace operators during foundries, melting shops and others. Available in customized options, our vibratory furnace charger is manufactured using high grade raw material.

-

VIBRATORY EQUIPMENTS

VIBRATORY SCREEN

The Matech Circular Vibrating Screen is widely used for grading and screening materials in the fields of minerals, quarry, building materials, etc. Our vibrating screen has multi-layers and its screen size is various, it can screen out many kind of materials with different sizes.